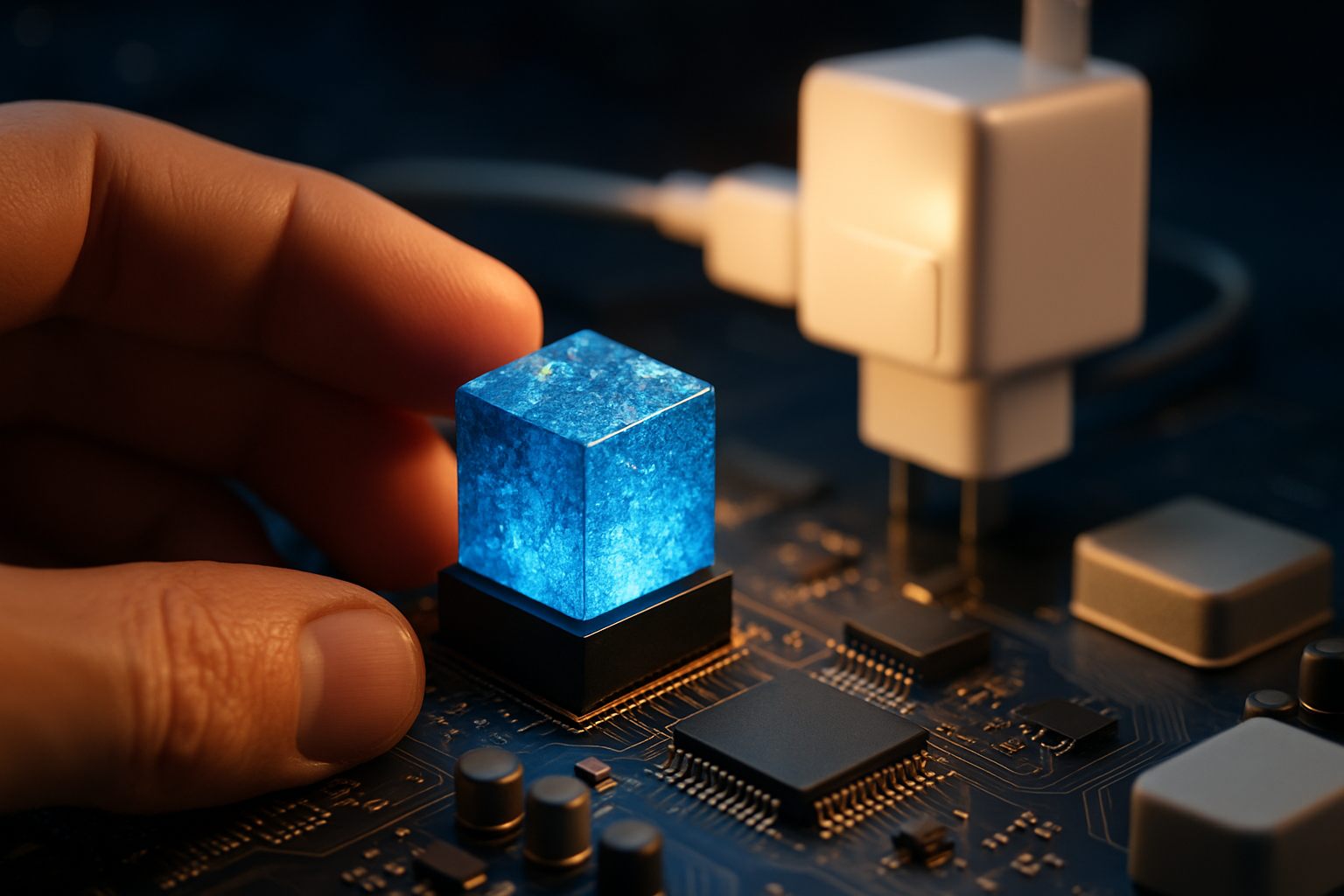

Thermal Cooling Revolution: Liquid Metal in Consumer Electronics

In a world where our devices are getting smaller and more powerful, keeping them cool has become a critical challenge. Enter liquid metal cooling, a groundbreaking technology that's set to transform thermal management in consumer electronics. This innovative approach leverages the unique properties of liquid metals to efficiently dissipate heat, potentially ushering in a new era of high-performance, compact devices that stay cool under pressure.

What is Liquid Metal Cooling?

Liquid metal cooling utilizes metal alloys that remain liquid at room temperature. These alloys, typically composed of gallium, indium, and tin, have thermal conductivity far superior to traditional thermal pastes or pads. When applied between a processor and its heat sink, liquid metal can transfer heat away from the chip much more efficiently than conventional materials.

The Science Behind the Solution

The key to liquid metal’s effectiveness lies in its unique physical properties. Unlike solid metals, liquid metals can conform perfectly to the microscopic imperfections on chip and heat sink surfaces, maximizing thermal contact. Their high thermal conductivity – often 10 to 100 times that of standard thermal compounds – allows for rapid heat transfer. Additionally, their liquid nature enables them to maintain consistent performance over time, unlike thermal pastes that can dry out or degrade.

Real-World Applications

While liquid metal cooling has been a staple in enthusiast PC building circles for years, it’s now making its way into mainstream consumer electronics. Several high-end gaming laptops have already adopted this technology, reporting significant temperature reductions and performance gains. For instance, some models have seen CPU temperature drops of up to 20°C under load, allowing for sustained high performance without thermal throttling.

Challenges and Considerations

Despite its promise, liquid metal cooling isn’t without challenges. The material is electrically conductive, which means precise application is crucial to prevent short circuits. It’s also corrosive to certain metals, particularly aluminum, limiting its compatibility with some heat sinks. Manufacturers must carefully design their cooling systems to contain the liquid metal and prevent it from migrating during use or transportation.

The Future of Cooling

As liquid metal cooling technology matures, we can expect to see it in a wider range of devices. Smartphones, with their intense thermal constraints, could benefit greatly from this technology. Imagine a phone that stays cool during intense gaming sessions or while recording 8K video. Beyond consumer electronics, liquid metal cooling could find applications in data centers, electric vehicles, and other high-performance computing environments.

Market Impact and Pricing

The adoption of liquid metal cooling is likely to impact the consumer electronics market significantly. While it currently adds a premium to device costs, with some high-end gaming laptops featuring this technology priced in the $2,000 to $3,000 range, economies of scale could bring these prices down over time. As the technology becomes more mainstream, we might see it become a standard feature in mid-range devices, potentially reshaping the performance landscape across various price points.

Environmental Considerations

An often-overlooked aspect of this technology is its potential environmental impact. By enabling more efficient cooling, liquid metal could lead to devices that consume less power and have longer lifespans. This could result in reduced electronic waste and lower energy consumption, aligning with the tech industry’s growing focus on sustainability.

As we look to the future of consumer electronics, liquid metal cooling stands out as a technology with the potential to redefine what’s possible in device performance and design. While challenges remain, the benefits of this innovative approach to thermal management are clear. As more manufacturers adopt and refine this technology, we may be on the cusp of a new era in electronics – one where overheating becomes a thing of the past, and our devices can truly unleash their full potential.